Our Rubber Molding Capabilities

Built in the heart of America to outlast the hardest jobs.

As a domestic rubber mold company rooted in Alabama, Spec Rubber powers our nation’s toughest industries with dependable custom rubber molding. Every gasket, seal, and part we produce reflects the quality and pride of U.S. manufacturing.

Our American-Based Rubber Molding Process

Compression Molding for Rubber

We handle heavy-duty compression molding for rubber with platen sizes up to 84", delivering large, durable parts for high-demand applications. This gives you strength, consistency, and production versatility for thick-walled or oversized components.

Transfer Molding

Transfer molding is ideal for tight tolerances and embedded inserts. We use it to manufacture intricate shapes and strong, reliable seals that hold up in mission-critical environments.

Injection Molding Rubber Products

Our facility features advanced rubber injection molding equipment, allowing for high-volume output with repeatable precision. Injection molding rubber parts helps us deliver speed and accuracy without sacrificing performance.

Rubber Molding Capabilities

While many rubber molding companies in the USA are limited by size, Specification Rubber steps up. Our massive 72″ and 84″ platen presses give us the firepower to mold oversized components that support America’s infrastructure, utilities, and public works—right here in Alabama.

Capabilities include:

84" platens for large-scale industrial molded rubber products

In-house waterjet for flat gaskets and rubber base molding

Molded rubber components up to 64" OD

Custom molding of small-to-large runs

Part marking and identification capabilities

Rubber-to-metal bonding for strength and stability

Vertical and horizontal rubber injection molding machines

Engineering support for custom rubber component manufacturing

Secondary Capabilities for Our Custom Molded Rubber Products

Precision Waterjet Cutting

Our in-house waterjet delivers accurate, high-speed rubber base molding and flat gasket cutting. It’s fast, clean, and ideal for custom rubber manufacturing that meets exact project specs.

Rubber Product Marking

We make it easy to track and identify parts by directly marking molded rubber products with compound codes or customer-specified details.

Rubber-to-Metal Bonding

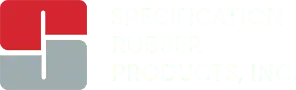

From valve seats to brackets, our rubber-to-metal bonding process helps fuse strength and flexibility in one powerful component, built to handle heavy stress and movement.

Request a Custom Quote

Looking for reliable, American-made rubber molding services that hold up to the real world?

Each method serves different needs. Compression molding works well for large, simple shapes or thick parts. Transfer molding is excellent for complex geometries or inserts. Injection molding is ideal for high-volume runs with tight tolerances.

Don’t worry—we’ll help you pick the right process for your part.

Yes. We offer rubber-to-metal bonding for parts that need durability, vibration resistance, or structural reinforcement. It’s widely used in industrial settings where molded rubber must work with metal components under pressure or movement.

With a full lineup of rubber molding processes and capabilities, including waterjet cutting, oversized platen presses, and both vertical and horizontal injection units, we’re ready for your most demanding jobs. Whether it's a one-off prototype or a full production run, we’ll deliver precision from start to finish.

Yes. We provide rubber product marking services that can include logos and compound IDs—helping with traceability, compliance, or customer branding.

Every part goes through rigorous inspection and material testing. We maintain process controls and documentation that meet industrial and municipal standards, so your custom molded rubber products arrive reliably, consistently, and ready for field use.

Frequently Asked Questions

See What Our Clients Are Saying

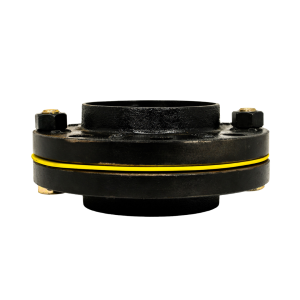

“Many times, the solution is simply to use the Toruseal® gasket from Specification Rubber because of its ability to catch and stop leak pathways based on its design. I highly recommend the Toruseal® Gasket for the peace of mind that it provides and its reliable performance.”

“This Gasket is far superior to standard flat gaskets. It costs a little more but the reassurance that it will not leak is worth it. We have never had an issue with the Toruseal® Gasket and highly recommend it for its reliable, leak-proof performance and peace of mind.”

"I placed my first order with Specification Rubber Products, and working with Paige Harkins was a great experience from start to finish. My contractor had us under some tough deadlines for Tyton® and MJ FKM gaskets, but Paige was able to push the deadline up to meet our demands and schedule. Because of this, the job was a success. It was such a positive interaction that I’ve already told our team to call Spec Rubber first for any gasket needs in the future."