Specification Rubber Products in Alabaster, Alabama, is expanding its operations in Shelby County with the purchase of a 120,000-square-foot warehouse that sits on more than 16 acres in Pelham. Located less than half a mile from Spec Rubber’s manufacturing headquarters, the new location will house finished goods inventory and raw materials. Spec Rubber, which celebrated its 55th-anniversary last year, manufactures molded rubber products for the waterworks industry.

“Since our doors opened in 1968, we’ve had six significant expansions and have outgrown our existing property,” said Spec Rubber President Steven Smith. “Purchasing this property ensures our strategic goals for growth are met in the next five to 10 years, and we are able to continue to meet the needs of our customers.”

Pelham Mayor Gary W. Waters said, “Specification Rubber has always been just across the road and has been a good neighbor. I expect the excellent relationship we’ve had with the company to continue as they move into Pelham to expand their operations.”

Spec Rubber expects the renovation of the existing warehouse to be complete in six months. The company expects to increase its workforce by about 10% with this expansion. “This is an investment in our facility, operations, and teammates,” Smith said.

“We are very excited to have Specification Rubber Products expanding a portion of their operation to the city of Pelham,” added Economic Development Director Michael Simon. “Specification Rubber Products’ acquisition of these 16 acres, future renovations of the 120,000 square-foot building, and the jobs created marks a significant investment of time and financial resources. We appreciate them choosing Pelham and look forward to fostering a great working relationship.”

Specification Rubber is a subsidiary of Birmingham-based AMERICAN Cast Iron Pipe Company, founded in 1905. Spec Rubber was recognized as a Shelby County Small Business of the Year in 2023 and one of Alabama’s safest manufacturers by Business Alabama magazine in 2019. For the past three years, the company has been named a Rubber News Best Place to Work. Visit specrubber.com to learn more.

The AMERICAN family of companies also manufactures fire hydrants, valves, ductile iron pipe and spiral-welded steel pipe for the waterworks industry and high-frequency-welded steel pipe for the oil and natural gas industries. AMERICAN’s diversified product line also includes fire pumps, structural casing and piling, and castings for large machinery. For more information, visit american-usa.com.

Specification Rubber is a subsidiary of Birmingham-based AMERICAN Cast Iron Pipe Company, founded in 1905. Spec Rubber was recognized as a Shelby County Small Business of the Year in 2023 and one of Alabama’s safest manufacturers by Business Alabama magazine in 2019. For the past three years, the company has been named a Rubber News Best Place to Work. Visit specrubber.com to learn more.

As the world around us evolves, a few things remain constant, such as the unwavering commitment to excellence that drives Specification Rubber Products (Spec Rubber) even as we celebrate our 55th anniversary. Founded in 1967 by E.W. “Bud” Quiggle, we officially opened our doors in March 1968.

As the world around us evolves, a few things remain constant, such as the unwavering commitment to excellence that drives Specification Rubber Products (Spec Rubber) even as we celebrate our 55th anniversary. Founded in 1967 by E.W. “Bud” Quiggle, we officially opened our doors in March 1968. Since 1968, the company has had four presidents, with Mr. Steven A. Smith currently presiding. All our leaders have been instrumental in our continued growth and success. However, despite all the advancements, one of Spec Rubber’s primary strategies has been to continue diversifying its product offerings and finding innovative ways to better serve our customers.

Since 1968, the company has had four presidents, with Mr. Steven A. Smith currently presiding. All our leaders have been instrumental in our continued growth and success. However, despite all the advancements, one of Spec Rubber’s primary strategies has been to continue diversifying its product offerings and finding innovative ways to better serve our customers.

As October arrives, trees shower us with waves of falling leaves in beautiful shades of red, orange, yellow, and brown.

As October arrives, trees shower us with waves of falling leaves in beautiful shades of red, orange, yellow, and brown. How We Can All Do Our Part

How We Can All Do Our Part

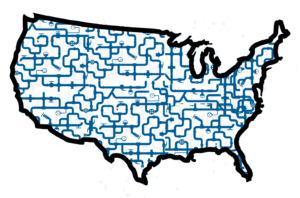

Pipes make America happen.

Pipes make America happen.

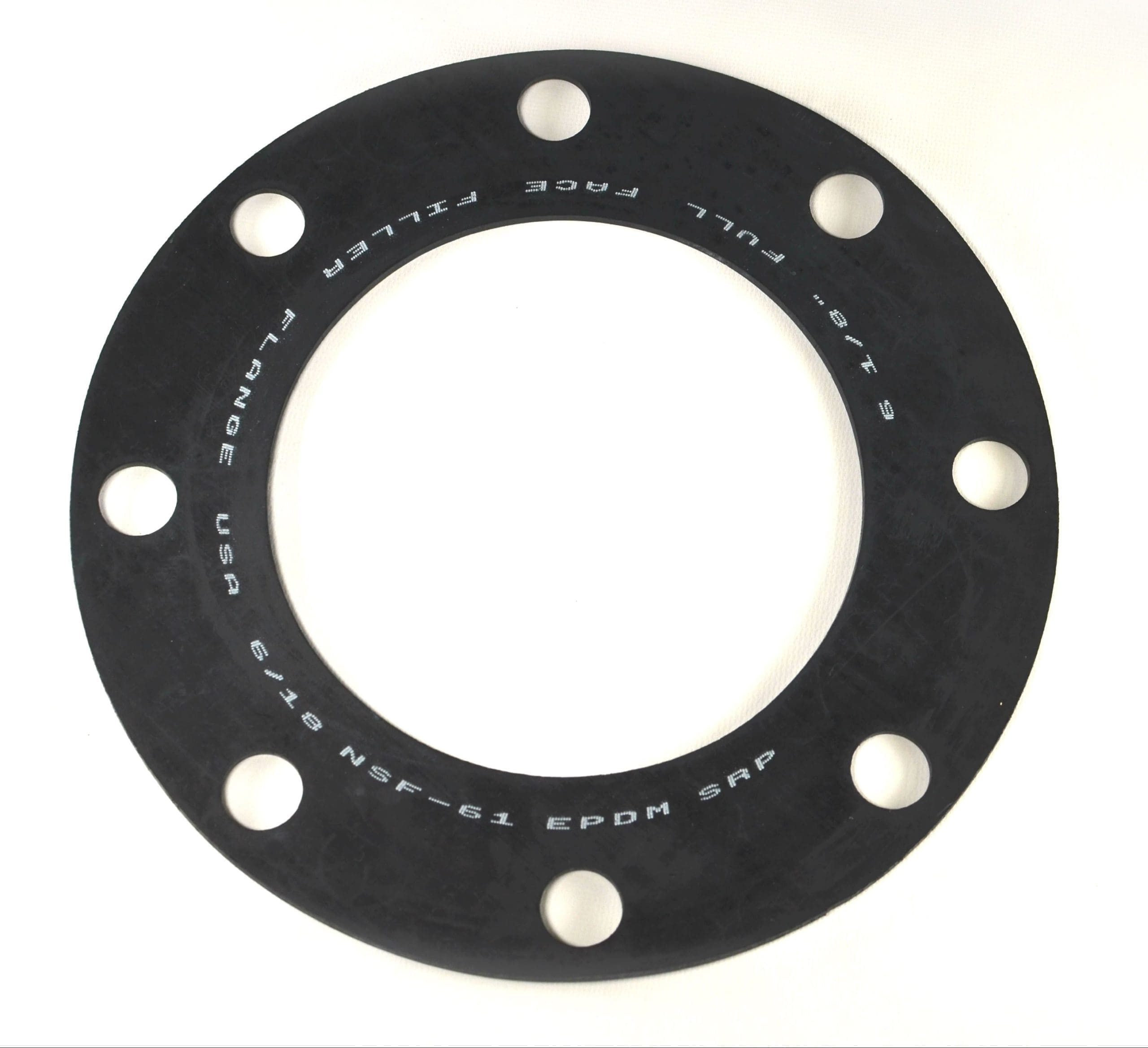

Spec Rubber is proud to be the winner of the 2023 Shelby County Small Business of the Year Award for businesses with 21 or more employees open one year or more. The Small Business of the Year awards were given out collaboratively by Calera Main Street, the Chelsea Business Alliance, Columbiana Main Street, Montevallo Chamber of Commerce, Montevallo Main Street, and The Shelby County Chamber. Businesses were judged based on their activities over the past three years, including staying power, employee growth, sales increase, response to adversity, and evidence of helping community-oriented projects. Spec Rubber has been operating in Shelby County for more than 55 years and is an established pillar of the local community. Spec Rubber has seen tremendous growth in recent years, and it is evident that their hard work and dedication have paid off. Spec Rubber is an ISO-certified manufacturer, and its waterworks products are NSF-61 certified, meaning these components meet the health and safety standards set forth by the National Sanitation Foundation for use in potable water applications. This certification has helped Spec Rubber stand out in the industry and has contributed to its success.

Spec Rubber is proud to be the winner of the 2023 Shelby County Small Business of the Year Award for businesses with 21 or more employees open one year or more. The Small Business of the Year awards were given out collaboratively by Calera Main Street, the Chelsea Business Alliance, Columbiana Main Street, Montevallo Chamber of Commerce, Montevallo Main Street, and The Shelby County Chamber. Businesses were judged based on their activities over the past three years, including staying power, employee growth, sales increase, response to adversity, and evidence of helping community-oriented projects. Spec Rubber has been operating in Shelby County for more than 55 years and is an established pillar of the local community. Spec Rubber has seen tremendous growth in recent years, and it is evident that their hard work and dedication have paid off. Spec Rubber is an ISO-certified manufacturer, and its waterworks products are NSF-61 certified, meaning these components meet the health and safety standards set forth by the National Sanitation Foundation for use in potable water applications. This certification has helped Spec Rubber stand out in the industry and has contributed to its success.