Most Americans take clean water for granted.

Most Americans take clean water for granted.

But for much of our history as a nation, clean water has been a struggle. Diseases caused by contaminated or polluted water aren’t nearly as prevalent as they once were – in large part because we’ve completely re-engineered how we protect, treat, and transport this vital substance.

To keep your water as clean as possible, it’s important to make sure that every object it comes in contact with – from the pipes and conduits that carry it to the rubber gaskets, fittings, and adhesives inside them – meets high-quality standards.

That’s the purpose of NSF/ANSI-61 (NSF-61): a set of regulations that make sure our water is safe and clean like it should be – and Specification Rubber helps make that happen.

The NSF-61 Certification Program Explained

The purpose of the NSF-61 certification program is simple: to provide proof that the company and its personnel understand the importance of keeping our water free from contaminants and impurities that can leach into it from the products that transport it.

The substances used by the industry to create our water infrastructure can be dangerous to humans. Drinking or consuming contaminated water can cause serious illnesses, which is why we have to be as careful as possible to prevent this from happening.

Companies with the NSF-61 designation for their products can demonstrate their commitment to the safety and sustainability of their products. To earn it, the company’s product must be evaluated by an independent and accredited third party that operates under the guidelines of NSF (the sponsoring organization of the standard) and ANSI (the American National Standards Institute).

This process involves:

- Product testing

- Material analysis

- Factory inspections

- Regular, on-site audits

- Ongoing surveillance of products

It’s not a one-shot deal, either; you have to stay certified on an ongoing basis.

If your products are certified, you gain the right to include language such as “NSF certified” or “NSF listed”, and can use the NSF certification mark. These are clear signals to your customers and constituents that you meet the necessary standards to produce a safe, community-friendly product.

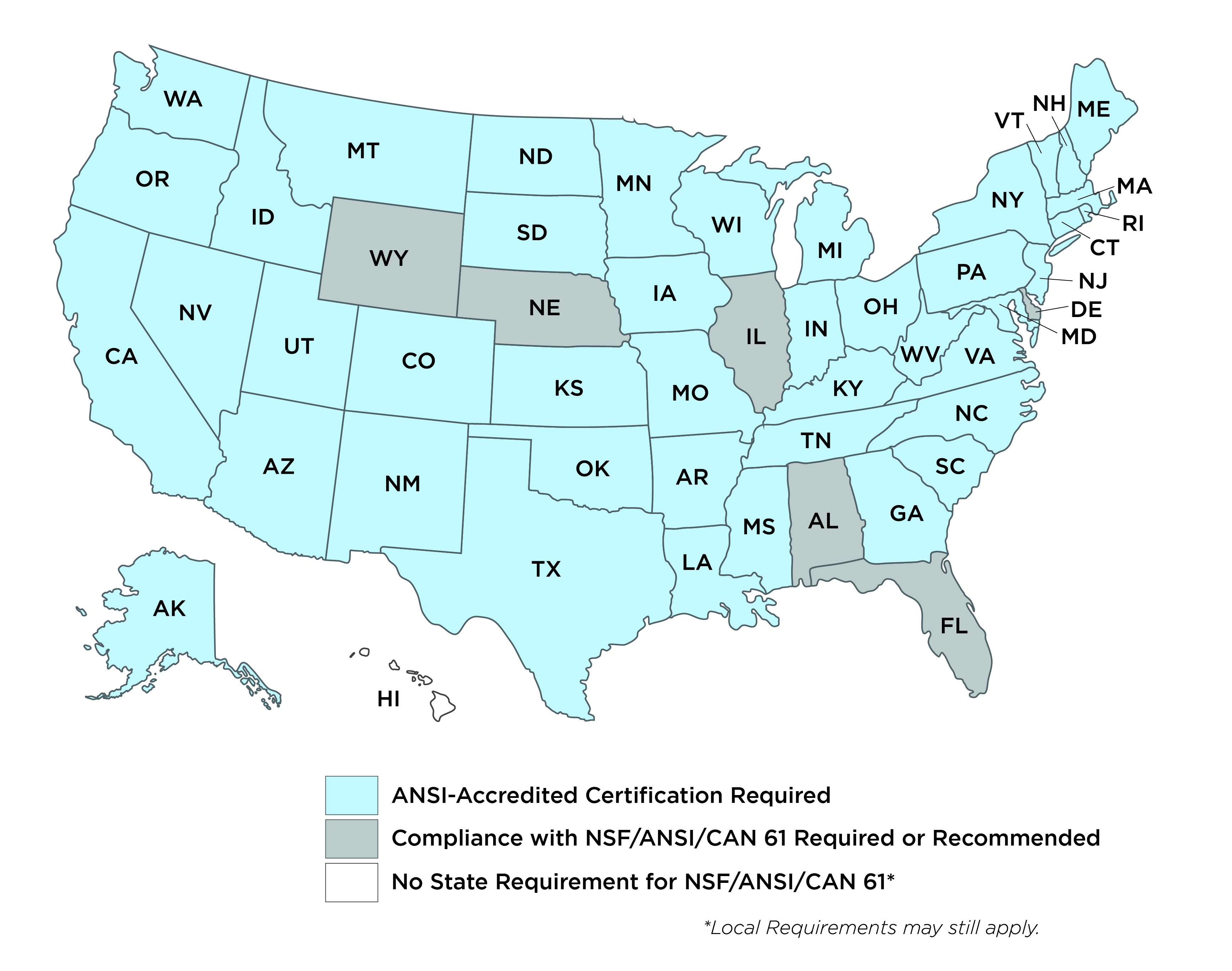

As of 2023, 49 states have laws or policies on the books requiring all drinking water system components to be compliant with or certified by NSF-61. (Louisiana is the only state that doesn’t.)

At Spec Rubber, we don’t settle for anything less than the highest standards for the cities and towns we serve, and that is why we stay fully certified to NSF-61. In becoming certified, our employees also achieve higher levels of training and deepen their understanding of how our rubber gaskets for water pipes and other components fit into the system as a whole – and the important role they play in protecting it.

Benefits and Details of the NSF-61 Certification Program

The NSF-61 certification process delivers benefits not just for employees and companies but also for residents.

These benefits include:

- A universally accepted verification of product quality

- Less liability for water systems

- A lower chance of expensive repairs and future required updates

- Easier decisions on what to purchase and which provider to choose for purchasers

- Confidence for residential consumers when it comes to buying and/or using certain components in the home

- A higher level of industry training and understanding for employees

- Easier access to markets all over the country for producers

Other facts concerning the program include the following:

- NSF began developing standards for drinking water in 1986 under a grant from the Environmental Protection Agency (EPA)

- Prior to 1986, NSF had been working in the water industry for over two decades

- A historical moment came in 2008, when NSF-61 mandated lower limits on lead content in plumbing products, spurred by regulations passed in California, Louisiana, Maryland, and Vermont

- NSF-61 is updated by a joint committee that includes end users, public health experts, and members of the water industry

- “Certification” is different from “compliance”; being compliant involves far less testing and regulation than becoming certified and is a much easier process to complete

The standards that NSF-61 covers can be found in the guidance produced and/or updated on a regular basis; you can access it here.

Protecting Water Now and in the Future

As a company with a full line of NSF-61 certified products, Spec Rubber is fully committed to maintaining clean water for the people we proudly serve.

Each new innovation we create goes through the process to ensure we’re creating the highest quality of safe and reliable products that we would want our own families to use.

Learn more about how we help our partners ensure NSF-61 compliance and keep our water system free of contaminants that no American should ever have to encounter.

Underneath the gr

Underneath the gr In 1968, when our doors opened for the first time, 75% of ductile iron piping used in America’s waterworks industry came from the foundries and foothills of Birmingham, Alabama.

In 1968, when our doors opened for the first time, 75% of ductile iron piping used in America’s waterworks industry came from the foundries and foothills of Birmingham, Alabama.

We also branched out from rubber gaskets to a wider range of essential products, including specialty mechanical molded goods for industrial applications. We’ve innovated with groundbreaking technology like our Barracuda® Gasket, which was released in 2014 and provides an easy (and colorful) way to show if a pipe joint is properly installed and restrained.

We also branched out from rubber gaskets to a wider range of essential products, including specialty mechanical molded goods for industrial applications. We’ve innovated with groundbreaking technology like our Barracuda® Gasket, which was released in 2014 and provides an easy (and colorful) way to show if a pipe joint is properly installed and restrained. produce our products right here in the USA, from the same local teammates you may see in the grocery store or at the ballpark.

produce our products right here in the USA, from the same local teammates you may see in the grocery store or at the ballpark.  We’ve been named the

We’ve been named the  continued to drive innovation

continued to drive innovation