Everyone loves a good deal, but a product’s total cost isn’t always apparent on the price tag. Quality matters, especially when we consider the impact that substandard products have on replacement and labor costs and your company’s reputation.

It’s Been a Crazy Year

Like most categories, the rubber industry has faced many ups and downs in the past 12 months as supply, demand, and purchasing power fluctuated with the uncertain business climate. But it wasn’t all bad news.

At Spec Rubber, we continued to thrive despite a variety of challenges, including low-price competition. Why? Even though our rubber gaskets cost more than products from foreign competitors, our customers understand the significant role gaskets play in quality assurance.

Quality Matters

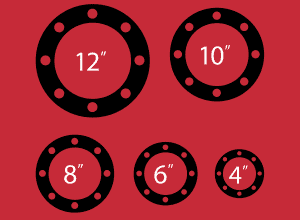

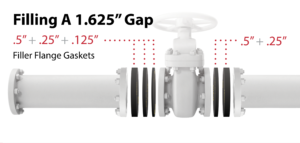

Unfortunately, gaskets are sometimes an afterthought when it comes to water system project planning. They are typically a tiny percentage of a project’s upfront cost. But the wrong gasket or seal can cost your business down the line.

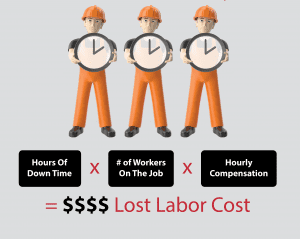

A lower cost gasket may look like a great value on an invoice, but it might not be such a good deal when you factor in the cost of product failure, expensive product recalls, legal fees related to NSF-61 problems, and damage to consumer confidence. Make no mistake, cheaper gaskets and seals have a shorter lifespan than higher-quality versions, so you will be paying for replacement parts and the corresponding labor more frequently.

What Makes a Quality Product?

Some foreign manufacturers add fillers to their compounds, and, making matters worse, they’re inconsistent with their material formulation. Spec Rubber uses ANSI/NSF certified compounds and maintains a consistently strict adherence to its formulation, as well as a very thorough and rigid ISO quality system for all compression, injection, and transfer molding.

See more of our rubber molding capabilities here!

Sure, you may pay more for quality products on the front end, But that initial outlay pays off via state-of-the-art process and technical experience that go into creating a safe and long-lasting rubber product.

You Can Count on Spec Rubber Products!

Are you confident in the quality you’re getting from your rubber gaskets and sealing products? This is especially critical for anyone in the waterworks industry, as faulty gaskets and seals can cause leakage that can cost you and the customer hundreds and thousands of dollars.

On the other hand, when you know the products you’re getting are quality-assured and long-lasting, you can be confident you’re getting what you’re paying for — in the best way possible!

To learn more about Spec Rubber’s products and our quality standards, contact us here.

Work Crew Efficiency

Work Crew Efficiency

officially ended. A Federal Holiday, Armistice Day, was established to commemorate all the men and women who served in the United States Armed Forces.

officially ended. A Federal Holiday, Armistice Day, was established to commemorate all the men and women who served in the United States Armed Forces.